Meadow is leading the industry on sustainability

Sustainability is at the core of our strategy – and our ambition is to provide the lowest carbon footprint and the most sustainable dairy and non-dairy ingredients to the world’s best companies.

Welcome to Meadow

Sustainability is at the core of our strategy – and our ambition is to provide the lowest carbon footprint and the most sustainable dairy and non-dairy ingredients to the world’s best companies.

We have an agile and customer-centric NPD process built on the best technical expertise, enabling rapid development of new products, categories and capabilities.

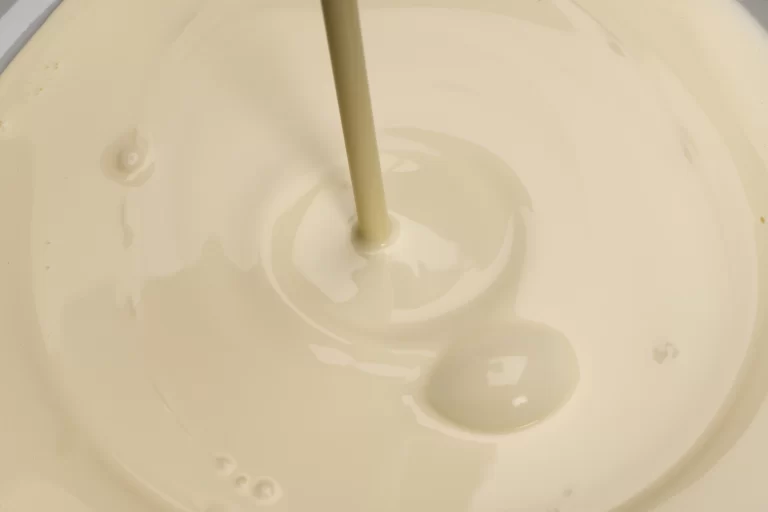

We’re committed to delivering superior quality products and achieve this through our unique ecosystem. We have the UK’s biggest milk balancing site, butteroil plant and fresh dairy ingredients facility and are the only independent chocolate crumb and sweetened condensed milk manufacturer in the UK. We also have the UK’s largest segregated plant-based facilities for dairy alternatives.

The Waste and Resources Action Programme (WRAP) estimates that 70% of food waste comes from households, 12% from hospitality, 2% from retail and a further 16% from the manufacturing industry. Food waste…

Between 80 and 90 million chocolate eggs are bought and consumed annually in Britain. And, with more than 44.5 million people planning to celebrate Easter in 2024, the holiday is the second…

International Women’s Day (8th March) is a global day celebrating the social, economic, cultural and political achievements of women. The day also marks a call to action for accelerating women’s equality. IWD…